For our latest blog post, we are looking back over a challenging but exciting EnerPHit refurbishment project that Gaysha completed back in 2015.

Our client had the budget to complete three Passivhaus refurbishments of existing properties as part of their plan to reduce carbon emissions. Gaysha was chosen to complete one of these projects at 13 Adams Row, a three storey former stables and coach house built in the 18th century.

As the existing architecture of the property made Passivhaus certification unachievable, Gaysha was tasked with refurbishing the property to EnerPHit standards.

Passivhaus versus EnerPHit standards

Before proceeding any further it may be useful to explain the terms Passivhaus and EnerPHhit. The Passivhaus Trust, the UK Passivhaus Organisation, defines a Passivhaus in the following way:

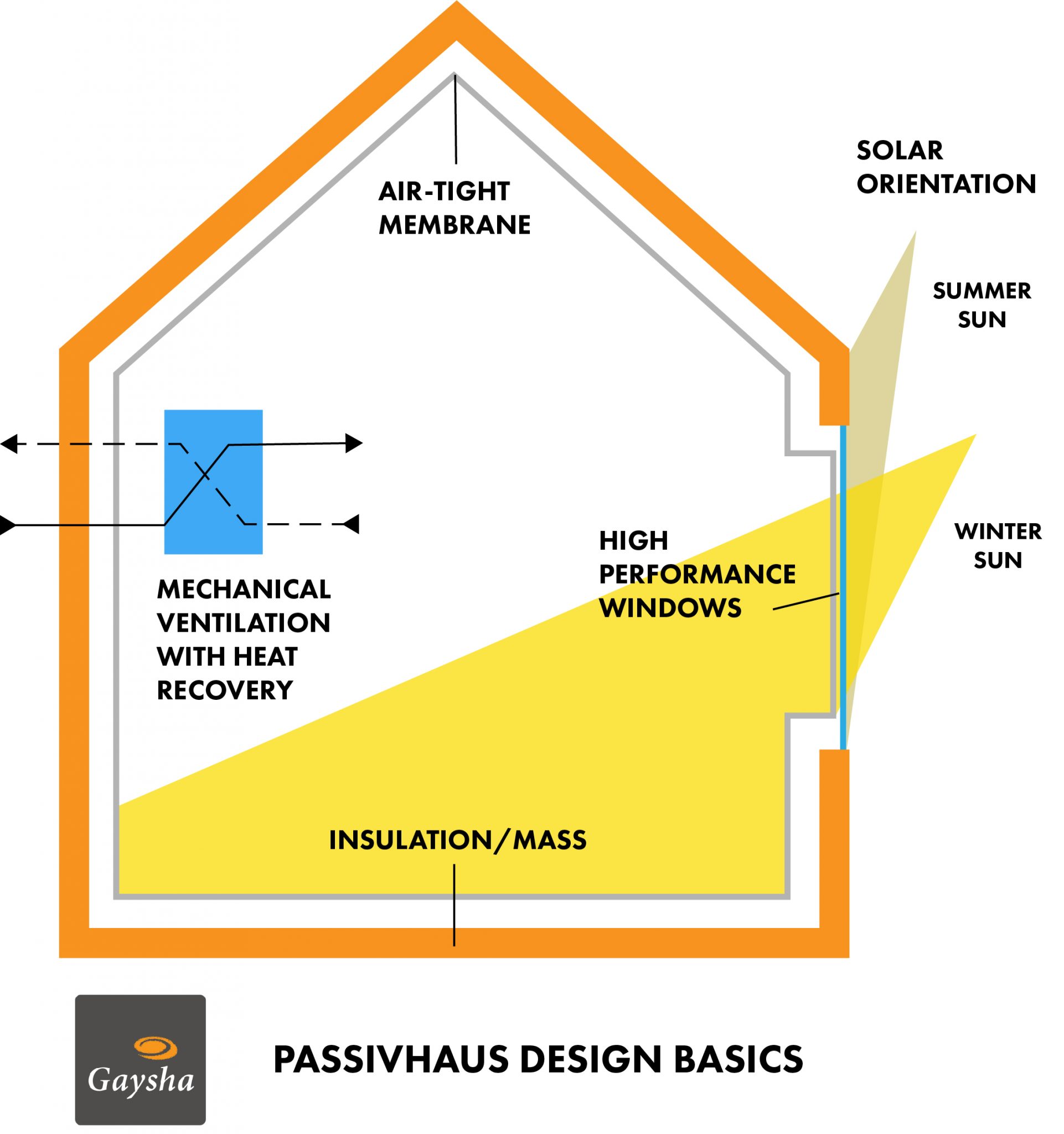

“A Passivhaus is a building in which thermal comfort can be achieved solely by post-heating or post-cooling the fresh air flow required for good indoor air quality, without the need for additional recirculation of air.”

So, a Passivhaus can achieve a high level of comfort for the occupants while requiring very little energy for heating and cooling. The building is completely air-tight with the heat from any stale air being removed from the building transferred to any fresh air coming in. In this way, the building can achieve a 75% reduction in heating requirements, compared to a standard new build.

A great video explaining Passivhaus in 90 seconds can be seen here.

EnerPHit is a slightly more relaxed standard for the retrofit of existing properties, where the architecture makes meeting the full Passivhaus standard unfeasible, mostly due to unavoidable thermal bridges in the existing structure.

The EnerPHit standard acknowledges the constraints imposed by working with an existing building and was created with lowered airtightness and heating demand criteria for these reasons.

13 Adams Row – the challenges of an EnerPHit Refurbishment

Owner: Grosvenor Great Britain & Ireland

Architect and PH Designer: Sturgis Carbon Profiling LLP

Structural Engineer: Hurt Pierce + Malcolm

Contractor: Gaysha Ltd

The aim of the project was to maintain all of the existing historical integrity of the property whilst delivering an energy efficient building to the highest modern standards. The EnerPHit refurbishment included the following upgrades:

- Super-efficient internal insulation

- New triple glazed windows

- Very high air-tightness

- Mechanical ventilation with heat recovery

A Heat Recovery Ventilation System comprises a Heat Recovery Unit and a network of ducting connected to each room. It works by continuously extracting air from the wet rooms of the property and at the same time drawing in fresh supply air from outside. 95% of the heat from the extracted stale air is recovered and is then reused to warm the filtered fresh air supplied to the main habitable rooms such as living rooms and bedrooms.

To break an EnerPHit refurbishment down into simple terms, the aim is to create an airtight membrane within the property so that the mechanical heat recovery ventilation system can control all airflow and recover heat from stale air before expulsion.

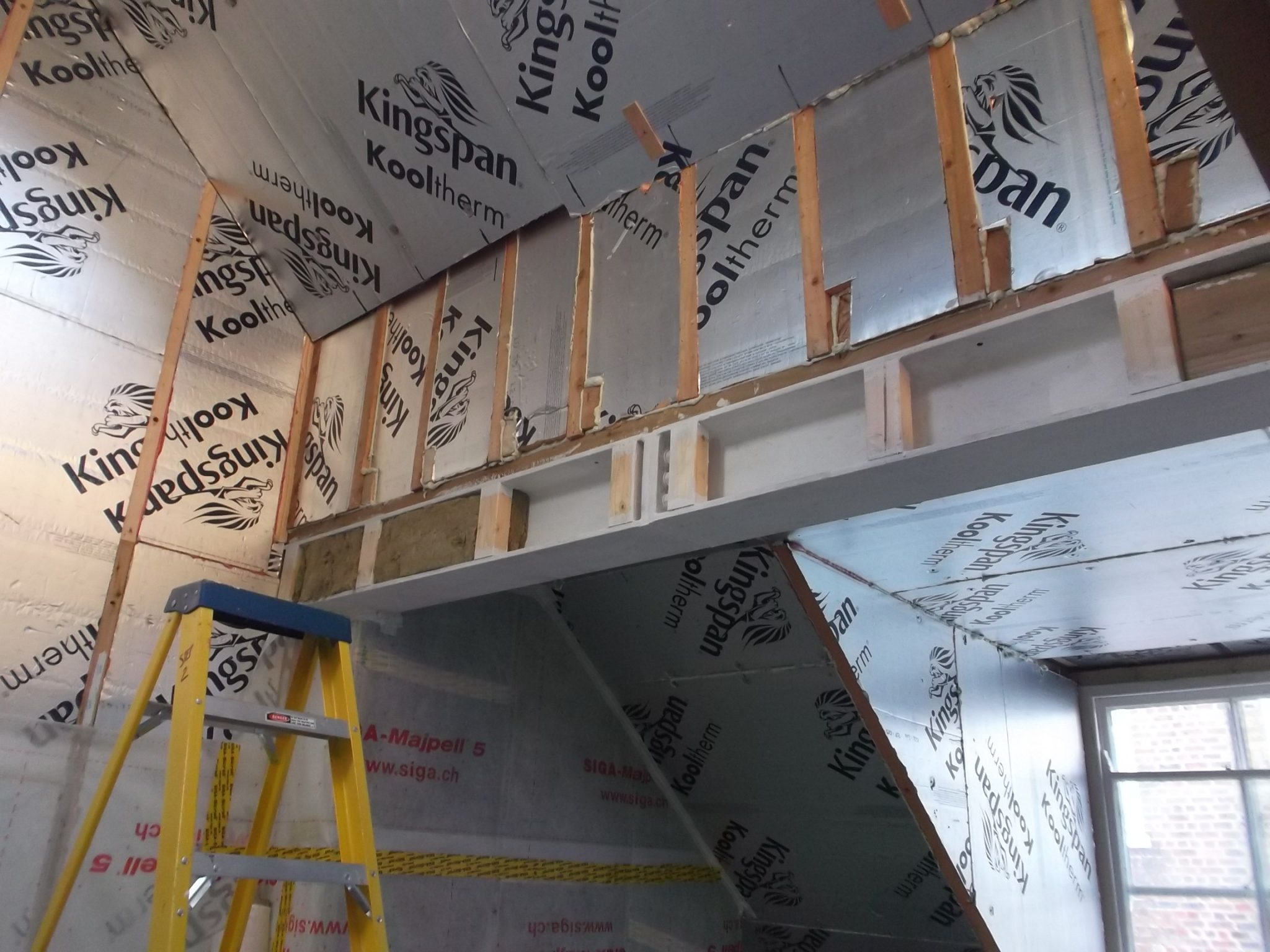

The main challenge when working to refurbish a period property to EnerPHit standards is that older properties often have irregular shaped rooms/roofs that can make both the installation of insulation and the creation of an airtight membrane challenging. The internal insulation on this project had to be meticulously cut to shape around the roof slopes, before being completely enclosed in an airtight vapour control layer with all joints sealed using specialist adhesive tape.

Achieving ambitious U-values and air-tightness is very complex and, if not designed properly, may reduce the indoor air quality and cause damage to the building fabric. For this reason, it is essential that competent and accredited Passivhaus professionals are engaged at a very early stage in the design process. Moisture levels inside the building should be monitored once the refurbishment is completed to ensure ventilation is adequate.

It is also very useful for on-site staff to be trained to use equipment to test the airtightness of the membrane as the project progresses.

Conclusion

Once the retrofit of the property was completed, a very good EPC rating of B87 was achieved and the project was granted PassivHaus EnerPHit Certification. The occupiers benefit from improved thermal comfort, as well as a reduction in energy bills of up to 86% compared to the building before refurbishment.

Upgrading heritage properties to Passivhaus standards requires special knowledge and expertise plus meticulous attention to detail – but achieving good energy efficiency standards is possible.

A design should be implemented that maximises improvements to energy efficiency whilst minimising adverse effects to the building fabric and historic value. Taking a balanced approach, which considers both environmental and historical concerns, can result in a property that is energy efficient and comfortable.

If you have a refurbishment project you’d like to discuss please get in touch.

Article by Dom Mahoney at Gaysha Ltd, a London-based fit out & refurbishment contractor operating across the residential, commercial and industrial sectors.

Gaysha Ltd, 5th Floor, 8-10 Grosvenor Gardens, London SW1W 0DH

Tel: 0203 887 3623 Email: info@gaysha.co.uk Web: www.gaysha.co.uk